Detail

Main driven shaft gears transfer power between shafts in any angle or speed, but specific gears apply to specific types, mainly decided by the mounting distance, free space and operation conditions. The basic types of bevel gears and their differences will be introduced in this article.

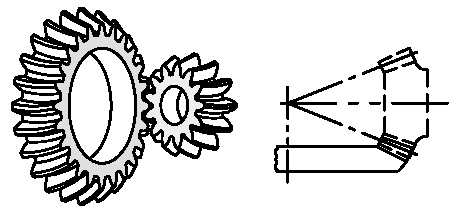

Straight bevel gears have teeth that are straight and parallel to the generators of the cone. This is the simplest form of a bevel gear. It resembles a spur gear, only conical rather than cylindrical. In straight bevel gears, each tooth impacts upon engaging its corresponding tooth, this can be solved by curving the gear teeth.

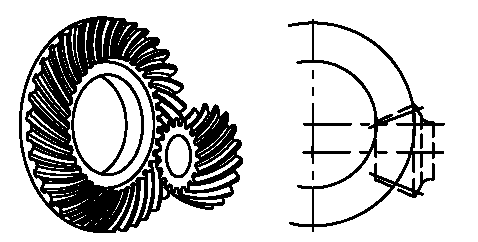

Spiral bevel gears are the most often used in vehicle differentials which are designed to produce less vibration and noise than straight bevel gears. A spiral bevel gear is a bevel gear with helical teeth formed along spiral lines on the gear face. The contact between the teeth starts at one end of the tooth and spreads across the entire tooth. The right hand of the spiral bevel is the outer half of the tooth, inclined to travel in the clockwise direction from the axial plane. The left hand of the spiral bevel travels in the counterclockwise direction. The main advantage of the spiral tooth over the straight tooth is that they engage more gradually and thus more smoothly. The result is a smoother transfer of force when each pair of teeth comes into contact.

Zerol bevel gears are an intermediate type of gear between straight and bevel gears. Their teeth are curved but not angled. They have the same orientation on the gear face as straight bevel gears.

Hypoid gears are spiral bevel gears where the axes of the two gears do not intersect. The pitch surface of a hypoid gear is a hyperbolic surface, as opposed to a spiral bevel gear which is normally conical. The hypoid gear places the pinion off-axis to the ring gear which allows the pinion to be larger in diameter and provide more contact area. In hypoid gear design, the pinion and ring gears are always of opposite hands, and the spiral angle of the pinion gear is usually larger than the angle of the ring gear.

May be interested